-

Windrower KSU-1

GENERAL DESCRIPTIONKSU-1 self-propelled mower is a reasonable way to solve several tasks simultaneously. It allows to mow and lay in swath the ear cereals, grain-bean and groat cultures, mow, compact and shred the forage grass with high efficiency. Powerful, maneuverable and universal KSU 1 mower ideally fits to farms, which actively use separate way of harvesting and deal in stockbreeding.

-

POWER PLANT

The universal self-propelled mower, depending on completion, is equipped with 4.75 L engine D-260 with 2100 rpm and power of 105 h.p., or 7.12 L engine D-260 with 2200 rpm and power of 157 h.p. Reliable, economy and simple engines recommended themselves in agricultural machine-building. -

Pneumatic systemSince 2014, the vehicles in basic set with D-260 engines are equipped with pneumatic system, in order to improve the machine autonomous features. It consists of 100 L receiver and compressor with automatic maintaining of pressure from 4 up to 8 bar, convenient tools and quick-disconnect clutch for connection, what makes operator’s work much easier. The air reserve in the system at running engines is enough for 5 minutes, what is sufficient for scheduled maintenance works performing.

Mounted universal systemIt provides aggregation of all adapters with universal self-propelled windrower KSU 1, without application of replaceable or additional parts. Therefore, the aggregation will take less than 15 minutes. It is widely known, that tractor hitch, consisting of lifting levers and lower longitudinal rods connected between each other by bracing of central rod and hydraulic cylinder, does not provide the field relief copying by reapers, what reduces the total effectiveness of operation.

HydraulicsThe universal self-propelled mower uses new decisions directed to improvement of reliability and convenience of maintenance. The integrated hydraulic tank for all systems (50 L) simplified design and improves convenience of maintenance. Availability of varying capacity pump provides much economical consumption of power taken off the engine. The fuel economy rate of the engine is increased. The integrated hydraulic control tank is used.

Adapters driveDF 900 and DF 700 roller transporting reaper is driven hydraulically, because there are no peak loads. It allows to adjust the reaper operating parameters (transporter speed, swath arrangement and reaper rpm) from the operator’s seat. The drive of adapters (GH 500c compacting mower, DM 350c frontal rotary mower, and JS 270 mounted mower-shredder) is performed through PTO installed on the vehicle.

-

_55016704a07e4.jpg)

Adviser systemThe universal self-propelled mower uses modern electrical equipment and on-board computer – Adviser system - which is targeted for convenient materiel maintenance and application.

- Collection and processing of information on condition of the machine systems and aggregates, output of the parameters on screen.

- Counting, storing and outputting the KSU quality parameters (operating time, travel, harvested area).

- Informing on necessity of repair or scheduled maintenance.

- Recording of consumed fuel.

Chassis driveThe chassis drive on KSU is made in the form of motor-wheels. Portal design of driving and driven axles with harvesting clearance of 1000mm provides required transporting clearance. KSU can travel over any swaths without any problem. The adjustable axle of balancing type with rocking angle ±8° possesses improved stability and maneuverability, especially when crossing channels and exiting the field to road.

Copying systemThe feature of patented relief copying system applied on the universal self-propelled mower is providing of field relief copying in longitudinal and lateral directions by all reapers proposed with the aggregate, thus increasing of their operating effectiveness. All the reapers connecting points are unified to provide maximum convenience and minimum aggregating time.

Controlled rear axleThe universal self-propelled mower design uses controlled rear axle system of portal type with two hydraulic cylinders and steering trapezoid. The controlled rear axle improves maneuverability of the machine in any field conditions. Original design of steering trapezoid has ability to turn actually on site, travel forward and backward without losing the control.

-

COMFORT AND FUNCTIONALITY

The universal self-propelled windrower KSU 1 is equipped with Comfort Cab which completely meets modern ergonomics requirements. The standard cabin set incorporates air-conditioner, heater, cooler and audio-preparation. The mower main controls are arranged on the operator’s RH control panel. Excellent round view is provided from the operator’s station. Steering column and driver’s seat are adjusted for the operator’s anatomical characteristics. Anatomically calibrated control joystick with control buttons. Informational panel with control system. In one word, the conditions for continuous and efficient operation are made.

-

ADAPTERS

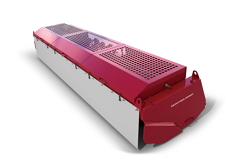

DF 900 (9.0m) roller transporting reaper

The roller transporting reaper is designed for mowing ear cereals and groats, green grass with laying the mowed grass into RH, central or LH swath, as well as doubled swath from two travels.

All working elements are hydraulically driven and controlled from the operator’s station. The efficiency comprises 10.5 hectares/hour at travel speed of 12km/h.

-

DF 700 (7.0m) roller transporting reaper

The roller transporting reaper is designed for mowing ear cereals and groats, green grass with laying the mowed grass into RH, central or LH swath, as well as doubled swath from two travels. Привод всех рабочих огранов гидрофицирован и управляется с рабочего места оператора. All working elements are hydraulically driven and controlled from the operator’s station. The efficiency comprises 8.0 hectares/hour at travel speed of 12km/h. -

GH 500R (5.0m) compacting mower

The compacting mower with segment-pin cutting apparatus is designed for mowing with compaction and without compaction. Also, the aggregate, together with universal self-propelled mower, can be used for laying the sowed and natural grass into swath.

The compacting mower efficiency comprises 5.8 hectares/hour at travel speed of 12km/h.

-

DM 350c (3.5m) frontal rotary mower

It is used for mowing thee high-crop and laid grass (with crop capacity higher than 150 quintal/hectare) with simultaneous drying of the mowed mass and laying it into swath. The compacting unit can be delivered together with the mower upon a separate order. The mower is designed for operation in all areas of plain agriculture, on the fields with flattened relief, and field slope not more than 8°. Operation on rocky terrain is not allowed. The efficiency comprises 6.0 hectares/hour at travel speed of 18km/h. -

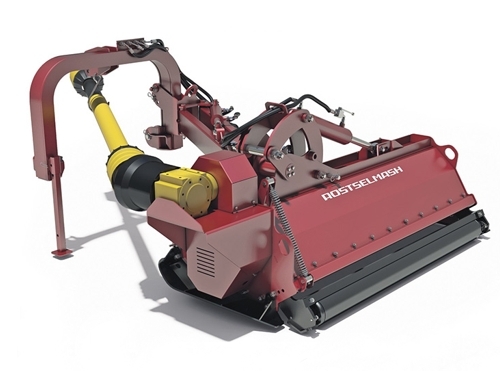

JS 270 (2.7m) mounted compacting mower

It is used for mowing, shredding and loading of natural and sowed grass and other forage cultures into near-travelling vehicle. The plant height should not exceed 2m on plain fields with a slope not more than 8 degrees. Except the comb seeding cultures used for green feeding of livestock and haylage laying.

The efficiency is up to 40t/h.

-

Get a best-price offer for windrower KSU-1