Rostselmash produced 10 000th VECTOR combine

The Rostselmash Company starts the year of its 85-anniversary from jubilee event. The 10 000th VECTOR grain harvester left the production conveyor.

— It is significant event for our staff, which is the real gift of the staff to the company’s jubilee, — said Valery Maltsev, Director General of Rostselmash. — In July, our company will celebrate the 85-anniversary, and production of the jubilee harvester is the original symbol of the year for us.

Another matching is symbolical too. Rostselmash started to renew its model line 10 years ago, and the first serial machines of the modern product line were namely VECTOR harvesters. On June 23, 2004, Rostselmash saw off solemnly the first batch of 20 harvesters. From the first months of operation, the harvester got the highest evaluations of its consumers. As the result, in a year of production start, VECTOR won in the country’s prestigious competition 100 best goods of Russia by winning a gold medal and the right to be marked with golden logo in nomination Innovation of the year.

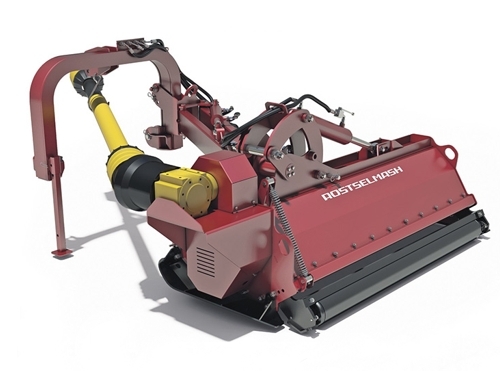

New level of comfort and efficiency came to the Russian farms together with VECTOR. Thus, the Rostselmash designers proposed another layout for the harvester — with centrally arranged cabin, behind which is the grain tank, and behind the tank is engine. Such layout has not been used in local harvesters before. The remoteness of engine as the main source of noise and vibrations increased the harvester operator working comfort. Additional cabin features provided place for exchanger, adjustable seat, steering wheel hydraulic booster, and conditioner (heater). The larger cabin glazing area provided the round view of the field and reduced the operator’s fatigability, and, as a result, increased his efficiency.

8 patented decisions were successfully used in VECTOR design. Particularly, the intellectual pseudo-sensor panel controlling technological processes was used in harvesting-building for the first time, and then it was successfully used on other models. The VECTOR cabin itself was the basis for designing the unified cabin for other Rostselmash harvesters.

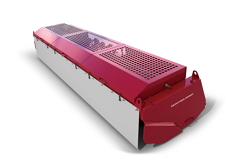

For 10 years of production, 4 modifications of this model were produced with indexes 410, 420, 420Е (with power plant meeting the European ecological standards), 450 Track (caterpillar).

At present, VECTOR remains not only the first harvester in modern product line of the company, but also one of the most demanded models of harvesting machines in Russia and abroad. It is not accidentally, that namely this model was selected as the basic model for assembly production arranged in the territory of Kazakhstan. Farmers, who select the harvesters of this model, achieve stably high parameters of efficiency. Thus, upon results of Russian competitions «The best machine operator» conducted by Rostselmash in 2010-2011, the harvesting leaders had seasonal grain output of 4164 and 6673 tons of cereals when operating VECTOR.

About us

The Rostselmash Group of Companies is included into five largest world manufacturers of agricultural machinery. The Group of Companies includes 13 enterprises. The production facilities are situated in the territories of Canada, Russia, USA, Ukraine and Kazakhstan. The Rostselmash product line comprises 24 types of agricultural materiel, and more than 150 models and modifications (grain-harvesting, forage-harvesting and soil-processing materiel, sprayers and grain protectants, etc.). The Rostselmash machinery is the selection of customers in 26 countries of the world. The branched dealer network guarantees operative servicing all over the world.